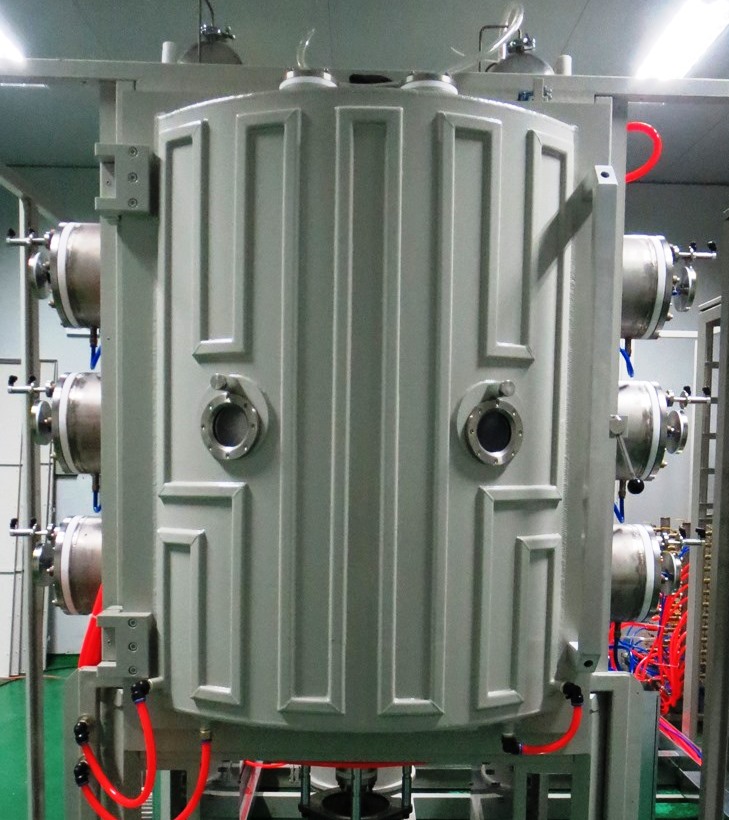

ZCK磁控多弧复合镀膜机

功能特性

该系列设备主要是集多弧离子、中频溅射、磁控技术于一体,可适应广泛镀膜靶材,无论金属还是其它化合材料介质都可以利用溅射工艺进行镀膜及成膜,使膜层附着力强、致密度高、从复度及颜色一致性好等特点,可镀制TiN(氮化钛)、TiC(碳化钛)、TiCN(碳氮化钛)、CrN(氮化铬)、CU(铜)、AU(金)、装饰膜等非金属及其化合物的膜层和复合膜层。设备由可编程序控制器(PLC)+触摸屏(HMI)组合成电气控制系统,实现全自动控制。

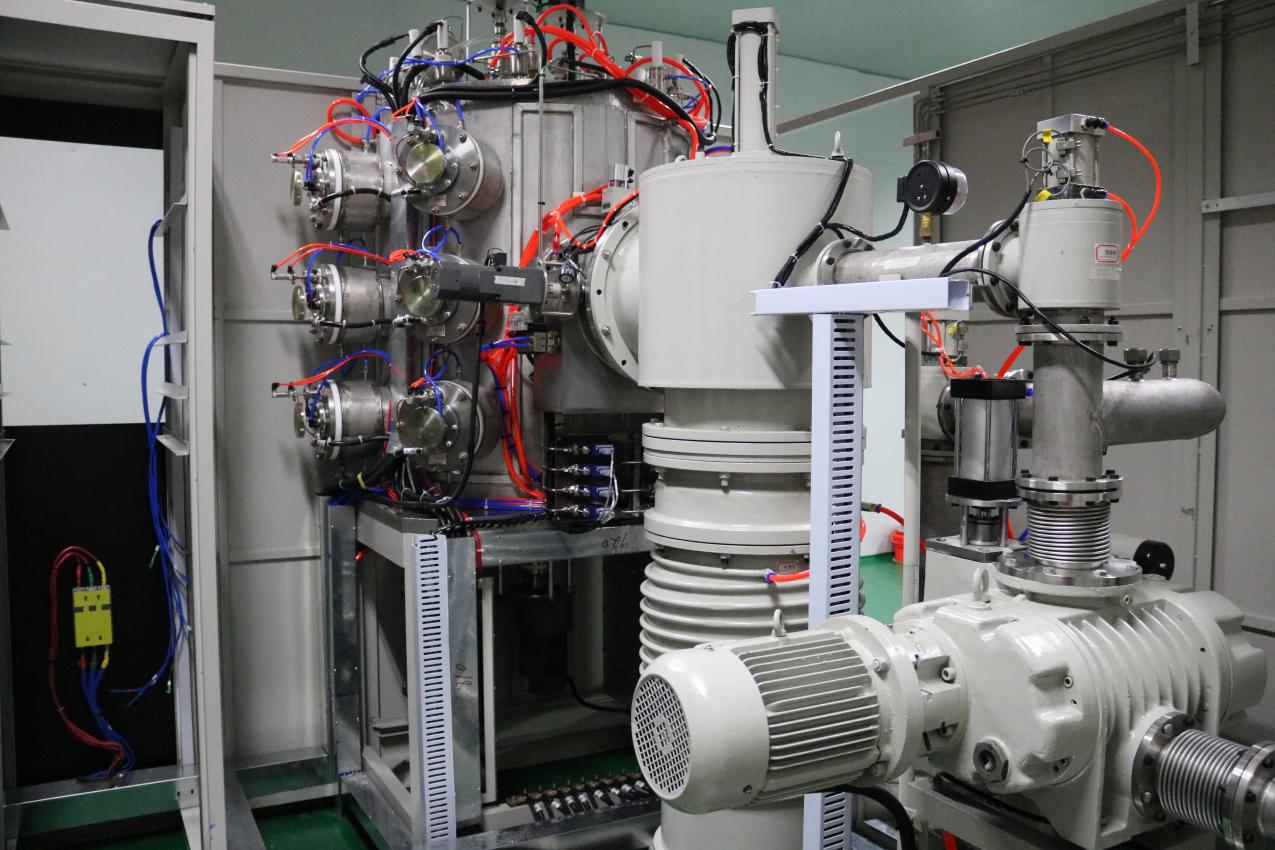

多弧离子镀膜机由镀膜室、N个电弧靶、弧电源,真空获得系统、旋转工件架、管状加热器、气路系统、水路系统、控制系统等组成。控制系统采用手/自动控制。沿用了新研制的阴极电弧离子源,这种新型弧源在工作时能有效减少大颗粒产生的数量,降低颗粒的尺寸,同时工作稳定,可在低电流时长时间稳定工作,所以镀出的膜层具有基体结合力好、膜层表面光洁、显微硬度高等优点。

该设备是一种高效、无污染离子镀膜设备,具有沉积速度快、离化率高、离子能量大、操作简单,成本低、生产量大等优点。

ZCK Magnetic Control Multi-Arc Compound Coating Equipment

LONG & SHINE designed and developed this new ZCK series of magnetic control multi-arc compound coating equipment. ZCK is for the multi-arc ion, mid-frequency sputtering, magnetic control technology, suitable for a board range of the coating required material, including metals and other chemical compounds. The finished coating has strong adhesion, high density and color consistency. The coating material can be different: TiN, TiC, TiCN, CrN, CU, AU, DLC, decorative coating, etc. The equipment is controlled by the programmable software (PLC) and touch screen (HMI) electric system, fully capable for automation.

Multi-Arc ion coating machine is consisted of coating room, multiple arc target, arc power supply, vacuum fetch system, rotation support, heater, gas system, water system, control system, etc. The newly developed cathode arc ion source is good for reduce the large particle number and longer working time in low current condition. It makes the coating surface good on adhesion, clean, smooth, and heavy duty.

The ZCK equipment is highly efficient and no pollution ion coating machine. It has the advantages of high deposition rate, high ionization rate, high ion energy, simply operation, low cost and high production capacity.

ZCK 磁控多弧复合镀膜机设备技术参数

ZCK Magnetic Control Multi-Arc Compound Coating Machine Technical Parameters

| 设备型号

Model |

ZCK-1000 | ZCK-1150 | ZCK-1200 | ZCK-1400 | ZCK-1600 |

| 真空室尺寸(mm)

Chamber(mm) |

1000x1200 | 1150x1200 | 1200x1300 | 1400x1300 | 1600x1300 |

| 制膜种类

Film |

黑色碳化钛、耐磨膜、七彩氧化钛、金色氮化钛、超硬膜、金刚石膜等

TiN, TiCN, ZrN, CrN, TiAIN, TIC,etc |

||||

| 电源类型

Power Types |

直流电源、中频电源、电弧电源、灯丝电源、活化电源、脉冲偏压电源

CD power, MF power, arc power, lamp power, bias power, pulse power. |

||||

| 多弧靶

Multi-Arc Target |

多弧靶5个或12个,1个或2个柱弧靶

Multi-Arc target 5 or 12 units, 1 or 2 units of Pole-Arc target. |

||||

| 孪生靶

Twins-Arc |

中频孪生柱靶或平面靶(1-4对)

Mid-frequency twins-arc or surface-arc (1 to 4 pairs) |

||||

| 真空室结构

Chamber Structure |

立式前开门结构(双层水套式或水槽式冷却)、后置抽气系统

Vertical door structure (dual-layer water cooling system),rear air pumping system. |

||||

| 真空系统

Vacuum System |

预抽泵+扩散泵+罗茨泵+维持泵(或选配:分子泵、旋片泵、深冷系统)

Sustaining pump, mechanical pump, roots pump, diffusion pump or molecule pump, etc. |

||||

| 加热系统

Heating System |

常温至350度可调可控(PID控温)、不锈钢加热管加热

Room temperature to 350 degrees Celsius controllable (PID temperature control), stainless steel heating pipes. |

||||

| 充气系统

Air Pumping System |

质量流量控制仪(1-4路)

Quality measure, flow measurement (1-4 routes) |

||||

| 极限真空

Ultimate Pressure |

6x10-4pa(空载、净室)

6x10-4pa (Empty load, empty chamber.) |

||||

| 抽气时间

Vacuum Time |

空载大气抽至5x10-3pa小于13分钟

From empty loaded to 5x10-3pa in less than 13 minutes |

||||

| 保压率

Pressure Retain |

1h≤0.6pa

|

||||

| 工件旋转方式

Tooling Rotation Mode |

上旋转或下旋转+公自转变频无级可控可调,0-20转/分

Upper rotation or lower rotation, revolution and self rotation, 20 rounds per minute |

||||

| 控制方式

Control System |

手动+半自动+全自动一体化/触摸屏+PLC

Manual, semi-auto, auto, touch screen, PLC |

||||

| 备注

Remark |

真空室尺寸可按客户产品及特殊工艺要求定做

Chamber size can be customized. Special processing customization. |

||||

真空镀膜设备

Vacuum Coating Equipment

超声波清洗

Ultra-sound Cleaning

干燥设备

Dry Out Equipment